XC-250 will provide a strong bond to marginally prepared steel with imperfections like tight rust or sharp edges. Use as a tank lining primer and finish coat inside tanks holding fresh or chlorinated water, waste water, gasoline, crude oil, etc. Also works great for concrete, fiberglass and galvanized metal. XC-250 is available in multiple colors and accepted for use in USDA/FDA inspected facilities.

XC-250 also comes in white and light gray with a 20-gallon minimum. Please call to place an order.

Get More InformationFeatures:

• Excellent adhesion even to marginally prepared steel with tight rust/sharp edges

• Cures to a tight film with low permeability

• Easy mix ratio

• Excellent abrasion resistance

• Long pot life for easy dip and roll or spray applications

• High solids

• Contains rust inhibiting Micaous Iron Oxide

• Outperforms standard DTM epoxies in resistance to chemicals and undercutting

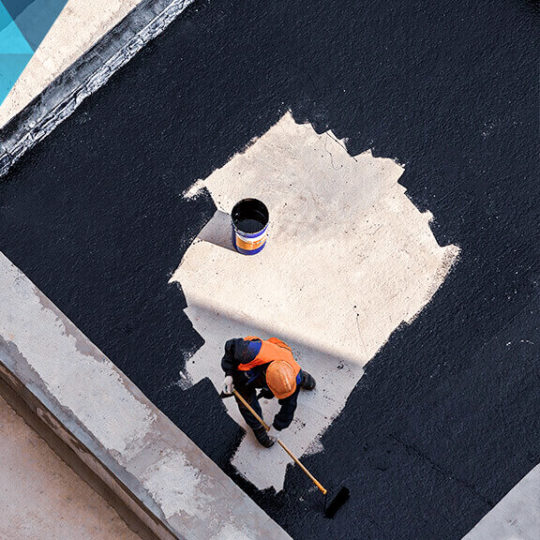

Coverage:

• Approximate coverage rate is 200 square feet per gallon per coat depending upon substrate and project requirements. Long pot life for easy dip and roll or spray applications.

Cure Time:

• Cures to a tight film with low permeability

• Open for Light Traffic: 72 hours @ 75° F

• Ready for immersion service: 7 days at 75°F

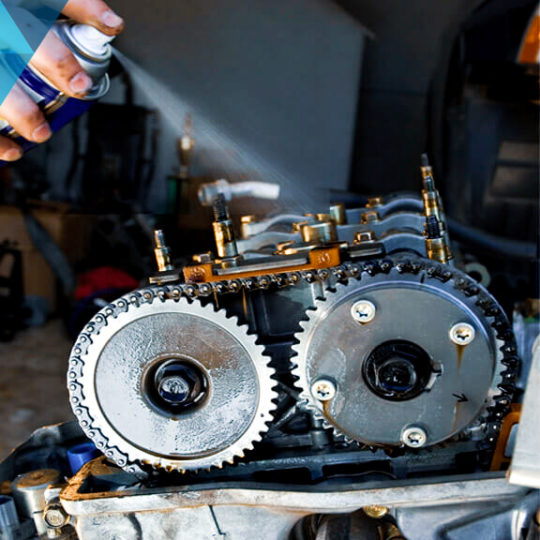

Application/Installation:

• Proper surface preparation is the most important step to a successful application.

• Apply by brush, roller or airless sprayer. When applying product, always consider the ambient, surface, and product temperature at the time and place of installation.

• Product test data is based on environmental temperatures of 75°F. Viscosity and working time are always affected by temperatures above or below that mark.

| Weight | N/A |

|---|